How to Get the Best Deal on CNC Milling Services

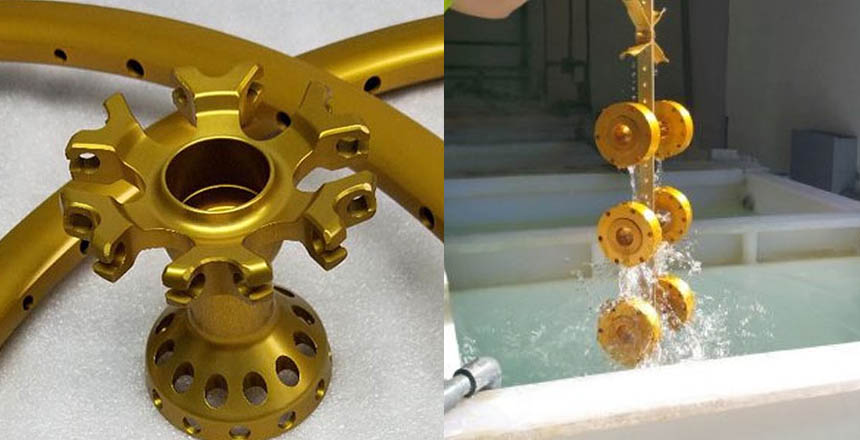

Today’s precision workmanship requires good quality machining. Manufacturing of those parts relies on the precision tools that are used for the work, and that means that precision workmanship needs to be done on the tools. CNC machining services are becoming more cost-effective as users and companies in need of precision tools increases, and there are ways of reducing those costs.